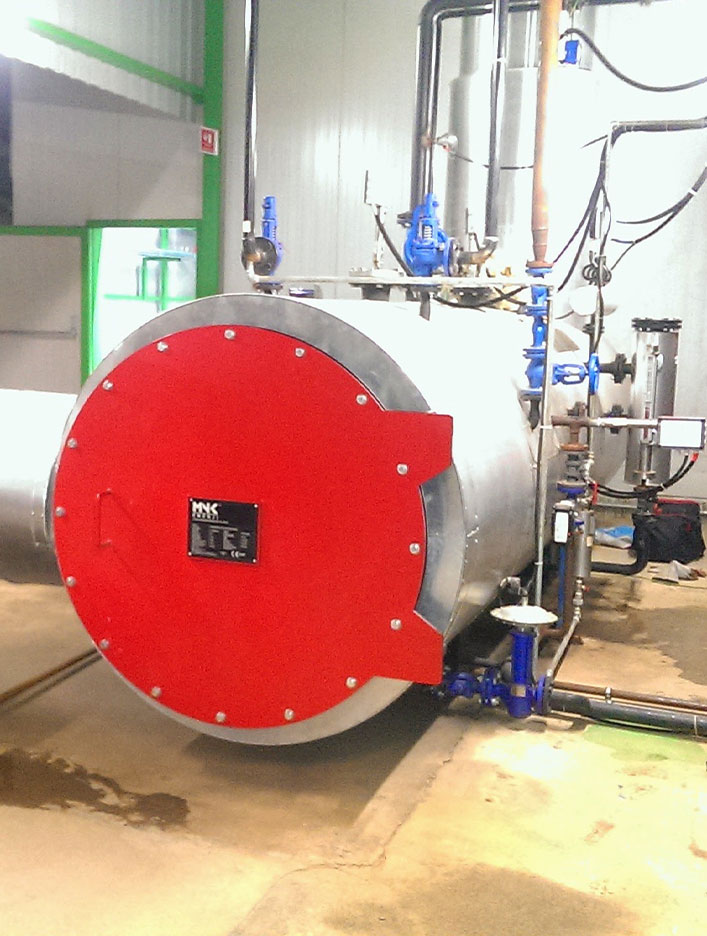

Waste Heat Boilers are used to produce Saturated and Superheated Steam are also called HRSG in Industry

Waste heat boilers produce hot water, saturated or superheater steam while cooling

the flue gases resulting from combustion or exothermic reaction.

Waste heat boilers can be produced with smoke-tube or water-tube and are preferred according to process conditions which are pressure and capacity.

If the gas stream is clean and the gas flow large water tube boilers with finned tubes are used as the boilers are compact.

As MNK, appropriate material selection according to the possible corrosion effect of the flue gases and online/ offline cleaning methods are integrated according to their contamination.

Waste heat boilers can be produced with smoke-tube or water-tube and are preferred according to process conditions which are pressure and capacity.

If the gas stream is clean and the gas flow large water tube boilers with finned tubes are used as the boilers are compact.

As MNK, appropriate material selection according to the possible corrosion effect of the flue gases and online/ offline cleaning methods are integrated according to their contamination.

Key Features

| Steam | Fuel Types | Capacity | Pressure | Steam Temperature | Gas Temperature |

|---|---|---|---|---|---|

| Saturated or Superheated | Sub-heated and Super-heated | up to 300 t/h | up to 136 bar g | up to 530°C | up to 1.700°C |

1) based on sensible heat

Advantages

High efficiencies

is achieved by choosing appropriate pinch

and approach points.

Long life

is ensured by using machining methods in all

welded preparations and with World-class welding equipment

and welders.

Vibration analysis

is performed, and trouble-free operation

is obtained.

Thermodynamic performance

Is achieved by calculation

with specially designed software and proven by site tests

High frequency welded spiral finned tubes

used for clean

gases makes compact design boiler.

Resistance welded rectangular finned tubes

used for

dirty gases makes compact design boiler.

Have any Questions?

Call us Today!

+49 163 9702005

About Our Company

One of the most important aspects of certification is traceability. MNK has

established a traceability system according to the heat number, order and

certificate numbers for all materials used in the pressure parts as required by the

standards. MNK transfers permanent hard stamps on the materials and keep the

records for 10 years...

Download PDF