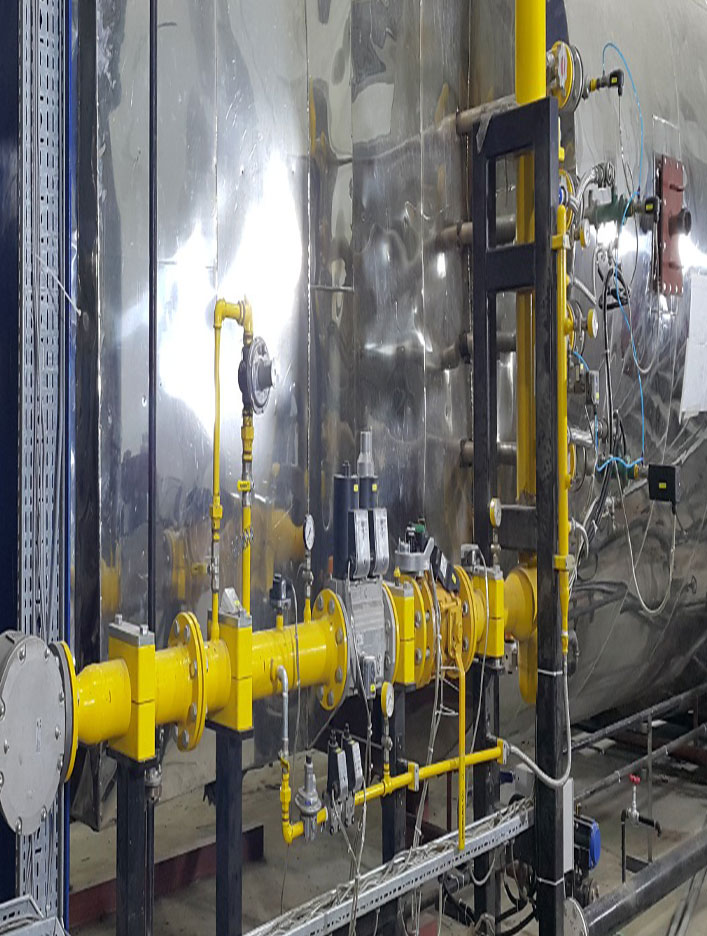

Supplementary Fired Waste Heat Boilers are used to increase cogeneration overall efficiency by burning additional fuel after the gas turbines.

Supplementary firing is an excellent way to generate additional steam in

cogeneration plants

Since the sensible heat recovered in the economizer in waste heat boilers is small compared to the heat of evaporation, most of the flue gas is thrown into the atmosphere without being used.

This waste heat is recovered in the economizer by increasing the evaporator capacity.

In addition, while 93% of the LHV value of the fuel is used in normal gas fired boilers, almost 100% is used in additional combustion boilers.

The oxygen required for additional post-combustion is provided by the oxygen in the exhaust of gas turbines operating with high excess air.

Since the sensible heat recovered in the economizer in waste heat boilers is small compared to the heat of evaporation, most of the flue gas is thrown into the atmosphere without being used.

This waste heat is recovered in the economizer by increasing the evaporator capacity.

In addition, while 93% of the LHV value of the fuel is used in normal gas fired boilers, almost 100% is used in additional combustion boilers.

The oxygen required for additional post-combustion is provided by the oxygen in the exhaust of gas turbines operating with high excess air.

Key Features

| Steam | Efficiency | Capacity | Pressure | Steam Temperature | Gas Temperature |

|---|---|---|---|---|---|

| Saturated or Superheated | up to %100 ** | up to 35 t/h | up to 60 barg | up to 530°C | up to 1.000°C |

1) for 5 MWe Taurus 60, bigger turbines are available

**) based on sensible heat

Advantages

High efficiencies

is achieved by choosing appropriate pinch

and approach points.

Long life

is ensured by using machining methods in all

welded preparations and with World-class welding equipment

and welders.

Thermodynamic performance

Is achieved by calculation

with specially designed software and proven by site tests

Fresh Air Fire

Steam generation operation is available when

the turbine is not operating.

High frequency welded spiral finned tubes

used for clean

gases makes compact design boiler.

Condensing economizer

Can recover very significant

amount of heat by cooling the flue gas

Have any Questions?

Call us Today!

+49 163 9702005

About Our Company

One of the most important aspects of certification is traceability. MNK has

established a traceability system according to the heat number, order and

certificate numbers for all materials used in the pressure parts as required by the

standards. MNK transfers permanent hard stamps on the materials and keep the

records for 10 years...

Download PDF