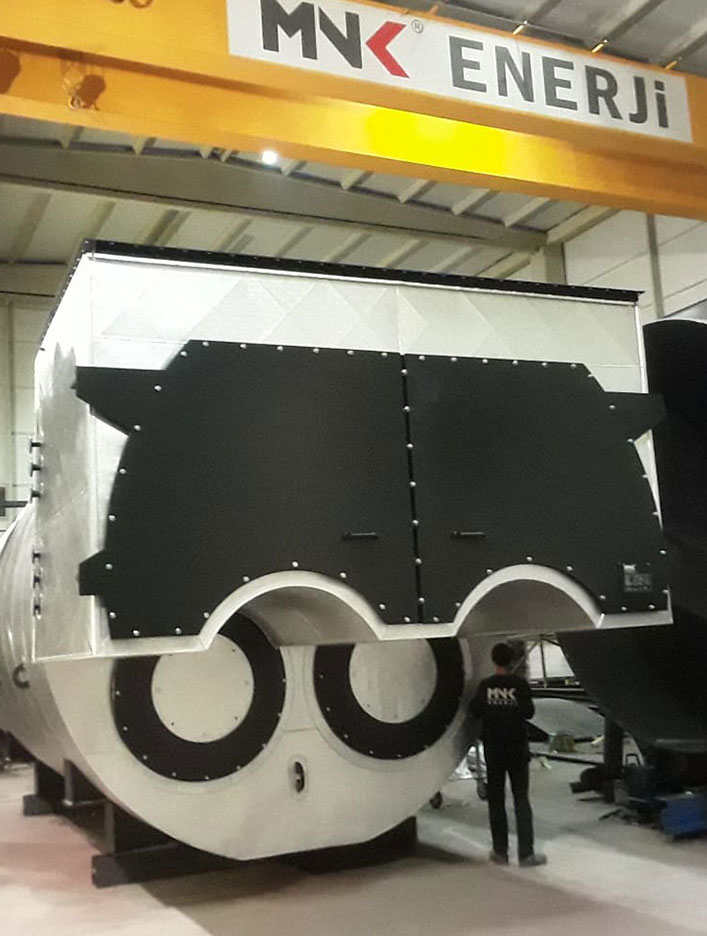

Shell Boilers are used to produce Saturated and Superheated Steam are also called Scotch Type in Industry

Food, dairy, textile, paper, chemical process industries pressure and capacity

requirements are medium-sized. The most ideal solution for such process steam

requirement is shell boilers.

Shell Boilers provides ease of production, operation and maintenance with its cylindrical and 3-pass construction. The furnace where the combustion takes place is made as corrugated. Its biggest advantages over water-tube boilers are, not sensitive to water quality and responds to peak steam capacities.

It is easy to make maintenance and repairs when it is necessary to reach and observe all of the heating surfaces. It is possible to commission very quickly by delivering skid mounted on burner, pump, economizer, control panel, etc. equipment

Shell Boilers provides ease of production, operation and maintenance with its cylindrical and 3-pass construction. The furnace where the combustion takes place is made as corrugated. Its biggest advantages over water-tube boilers are, not sensitive to water quality and responds to peak steam capacities.

It is easy to make maintenance and repairs when it is necessary to reach and observe all of the heating surfaces. It is possible to commission very quickly by delivering skid mounted on burner, pump, economizer, control panel, etc. equipment

Key Features

| Steam | Fuel Types | Capacity | Pressure | Efficiency | Design Life | Emission |

|---|---|---|---|---|---|---|

| Saturated or Superheated | Gas, Oil, Hydrogen | up to 70 t/h | up to 30 bar g | up to 105% | 30 years | <20 mg/kW |

1) with twin furnace

2) depends on capacity

3) based on sensible heat

Advantages

High efficiencies

Which are 95% can be obtained with the

feed water economizer, 97,5% with the recuperator and up

to 105% with the condensing economizer according to the sensible heat.

Long life

is ensured by using machining methods in all

welded preparations and with World-class welding equipment

and welders.

Low Emissions

Are achieved thanks to the perfect

integration between the boiler and the burner.

Logo Design

is achieved by calculation

with specially designed software and proven by site tests.

No water fluctuation

in the boiler because of well design

homogeneous heat flow.

Refractorless design

On on burner and doors eliminates the

problems and increase the efficiency with water-cooled

chamber between the burner connection plate and the furnace.

Have any Questions?

Call us Today!

+49 163 9702005

About Our Company

One of the most important aspects of certification is traceability. MNK has

established a traceability system according to the heat number, order and

certificate numbers for all materials used in the pressure parts as required by the

standards. MNK transfers permanent hard stamps on the materials and keep the

records for 10 years...

Download PDF